10 Best Laser Cutting Machines 2026 in the United States

Winner

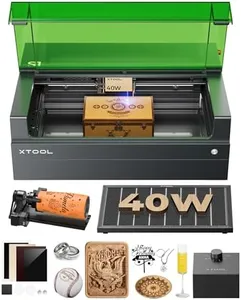

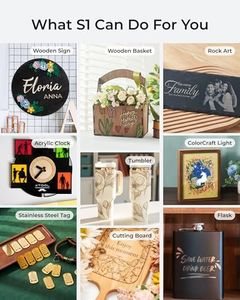

xTool S1 40W Laser Cutter and Laser Engraver for Tumblers, 23.93" x 15.16" Bed Size, 600mm/s Speed, Laser Engraving Machine, Laser Engraver for Wood and Metal, Acrylic, Big Project - Rotary Bundle

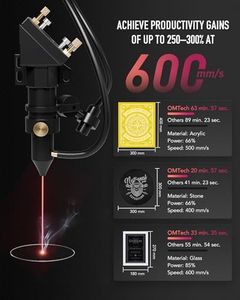

The xTool S1 40W Laser Cutter and Engraver is a robust machine designed for diverse and large-scale projects. One of its main strengths is the powerful 40W laser, which effortlessly cuts through thick materials like 18mm cherry wood in a single pass. The large cutting area of 23.93” x 15.16” makes it suitable for big projects such as door signs or batch engraving items like dog tags. With cutting speeds of up to 600mm/s, it ensures high productivity and efficiency.

Most important from

272 reviews

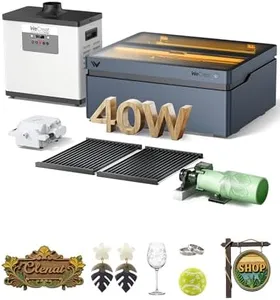

WECREAT Vision 40W Laser Cutter and Engraver Machine, with Auto-Lifting, HD Camera, 4-in-1 Rotary, 600mm/s Speed, Diode Laser Engraver for Tumblers Wood Metal Acrylic Small Business - Rotary Bundle

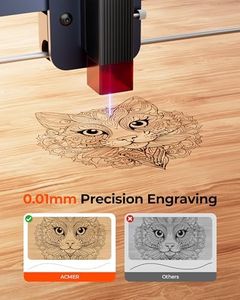

The WECREAT Vision 40W Laser Cutter and Engraver is a solid choice for small businesses or hobbyists looking for a powerful and versatile cutting machine. Its 40W laser power, achieved by combining eight 5.5W lasers, allows it to cut through relatively thick materials like 18mm wood and 15mm dark acrylic in just one pass, saving time compared to other machines in this class. The cutting speed of up to 600mm/s is quite fast, letting you complete batch jobs efficiently. The machine also offers excellent precision with 0.01mm accuracy, which is great for detailed engraving work on items like jewelry, mugs, and glass. A standout feature is the built-in HD camera with auto-focus, simplifying setup by reducing positioning time and material waste.

Most important from

138 reviews

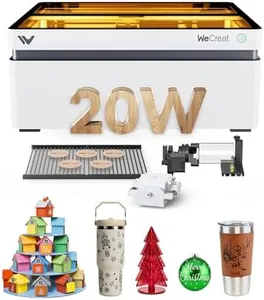

WECREAT Vision 20W Desktop Laser Engraver, Auto-Lifting for 5.5" Material, Smart Camera for Easiest Positioning, 600mm/s Speed, Laser Engraving Machine for Tumblers Wood Acrylic DIY Craft Gifts Making

The WECREAT Vision 20W Laser Engraver is a well-rounded machine suited for both hobbyists and professionals. With a powerful 20W laser, it offers high precision with 0.01mm accuracy and a rapid cutting speed of 600mm/s, making it efficient for batch engraving. The cutting area is adaptable due to its auto-lifting design, accommodating materials up to 5.5 inches thick, which adds convenience by eliminating manual adjustments. The engraver can handle various materials such as wood, metal, acrylic, and tumblers, making it versatile for different DIY projects.

Most important from

138 reviews

Top 10 Best Laser Cutting Machines 2026 in the United States

Winner

xTool S1 40W Laser Cutter and Laser Engraver for Tumblers, 23.93" x 15.16" Bed Size, 600mm/s Speed, Laser Engraving Machine, Laser Engraver for Wood and Metal, Acrylic, Big Project - Rotary Bundle

xTool S1 40W Laser Cutter and Laser Engraver for Tumblers, 23.93" x 15.16" Bed Size, 600mm/s Speed, Laser Engraving Machine, Laser Engraver for Wood and Metal, Acrylic, Big Project - Rotary Bundle

Chosen by 1217 this week

WECREAT Vision 40W Laser Cutter and Engraver Machine, with Auto-Lifting, HD Camera, 4-in-1 Rotary, 600mm/s Speed, Diode Laser Engraver for Tumblers Wood Metal Acrylic Small Business - Rotary Bundle

WECREAT Vision 40W Laser Cutter and Engraver Machine, with Auto-Lifting, HD Camera, 4-in-1 Rotary, 600mm/s Speed, Diode Laser Engraver for Tumblers Wood Metal Acrylic Small Business - Rotary Bundle

WECREAT Vision 20W Desktop Laser Engraver, Auto-Lifting for 5.5" Material, Smart Camera for Easiest Positioning, 600mm/s Speed, Laser Engraving Machine for Tumblers Wood Acrylic DIY Craft Gifts Making

WECREAT Vision 20W Desktop Laser Engraver, Auto-Lifting for 5.5" Material, Smart Camera for Easiest Positioning, 600mm/s Speed, Laser Engraving Machine for Tumblers Wood Acrylic DIY Craft Gifts Making

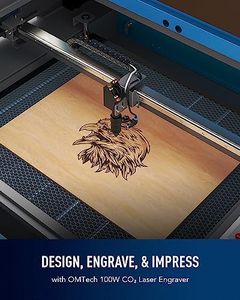

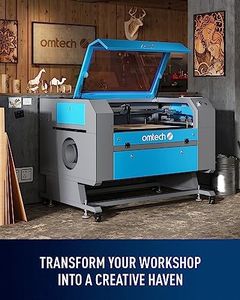

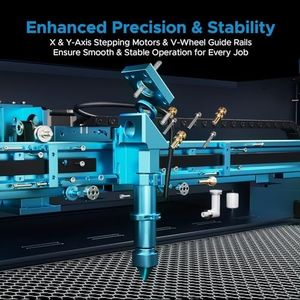

OMTech 100W CO2 Laser Engraver with LightBurn, 28"x20" Laser Engraving Cutting Machine with 4 Way Pass Through Air Assist Water Pump Wheels, Industrial Laser Cutter for Wood Glass Acrylic More

OMTech 100W CO2 Laser Engraver with LightBurn, 28"x20" Laser Engraving Cutting Machine with 4 Way Pass Through Air Assist Water Pump Wheels, Industrial Laser Cutter for Wood Glass Acrylic More

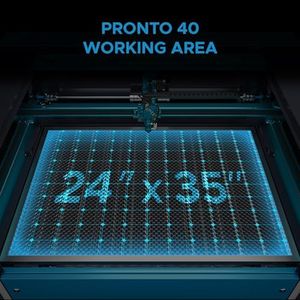

OMTech Pronto 90W CO2 Laser Engraver & Cutter – 35"x24" Workspace, 1000mm/s Speed, Autofocus, Air Assist, 2-Way Pass, for Wood, Acrylic & More

OMTech Pronto 90W CO2 Laser Engraver & Cutter – 35"x24" Workspace, 1000mm/s Speed, Autofocus, Air Assist, 2-Way Pass, for Wood, Acrylic & More

OMTech 60W CO2 Laser Engraver, 28x20 Inch Laser Engraving Cutting Machine with Autolift 4 Way Pass Air Assist Water Pump, Commercial Laser Engraver Cutter for Wood Glass Leather More

OMTech 60W CO2 Laser Engraver, 28x20 Inch Laser Engraving Cutting Machine with Autolift 4 Way Pass Air Assist Water Pump, Commercial Laser Engraver Cutter for Wood Glass Leather More

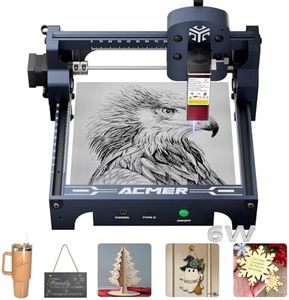

ACMER S1 Laser Engraver, 6000mW Laser Engraver Machine Higher Accuracy Wood Cutter and Engraving Machine with Working Area 130x130mm,0.04mm Laser Spot for Wood Acrylic Metal Glass

ACMER S1 Laser Engraver, 6000mW Laser Engraver Machine Higher Accuracy Wood Cutter and Engraving Machine with Working Area 130x130mm,0.04mm Laser Spot for Wood Acrylic Metal Glass

AlgoLaser 10W Portable Laser Engraver Machine: Smart Laser Engraver/Cutter with 3.5" Touchscreen & 2.0 AlgoOS System - Hand Draw/Wireless Transmission/Offline - Laser Engraving for Wood,Metal,Glass

AlgoLaser 10W Portable Laser Engraver Machine: Smart Laser Engraver/Cutter with 3.5" Touchscreen & 2.0 AlgoOS System - Hand Draw/Wireless Transmission/Offline - Laser Engraving for Wood,Metal,Glass

OMTech 60W CO2 Laser Engraver with LightBurn and Water Chiller, 16"x24" Laser Engraving Cutting Machine with 2 Way Pass Air Assist Digital Controls, Commercial Laser Cutter for Wood Glass Acrylic More

OMTech 60W CO2 Laser Engraver with LightBurn and Water Chiller, 16"x24" Laser Engraving Cutting Machine with 2 Way Pass Air Assist Digital Controls, Commercial Laser Cutter for Wood Glass Acrylic More

CREALITY FALCON A1 10W Laser Engraver, 80W Enclosed Laser Cutter and Engraver Machine with Air Assist, Smart Camera Positioning, 600mm/s Speed, Smart Material Recognition, Ideal for Wood & Metal

CREALITY FALCON A1 10W Laser Engraver, 80W Enclosed Laser Cutter and Engraver Machine with Air Assist, Smart Camera Positioning, 600mm/s Speed, Smart Material Recognition, Ideal for Wood & Metal

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.